How we create knives

Damascus steel made in-house

We do it all in-house ourselves. All steel is hand forged in our workshop on the beautiful Fleurieu Peninsula, South Australia.

Only the best steels are used to guarantee the toughest and sharpest knives available.

All of our forged knives are made from our own pattern welded steels. We forge weld hundreds of layers of high carbon and high nickel steels together, to form what is known as Damascus steel.

Forging

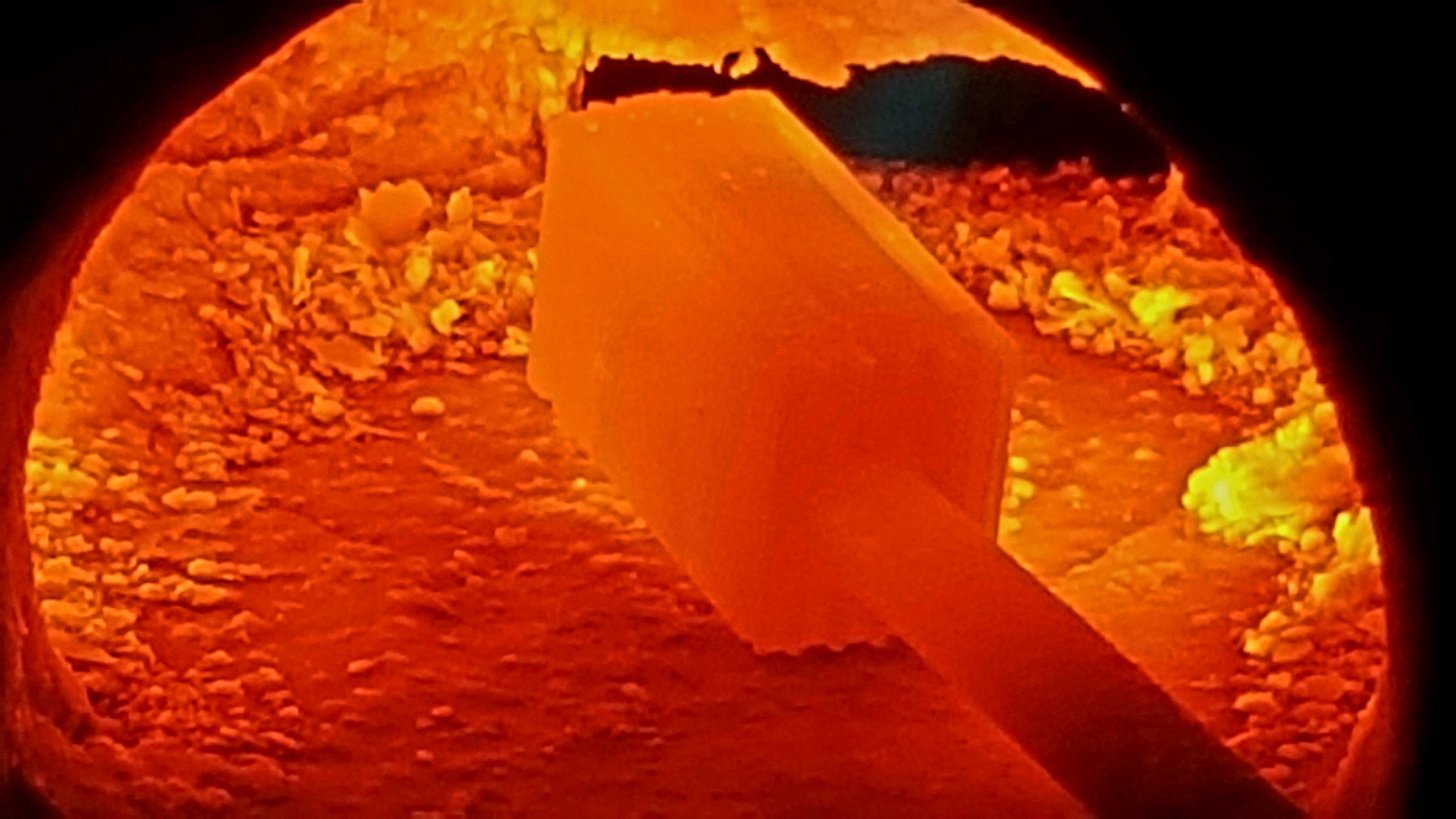

We use several methods to weld, forge and shape our blades. We start by cutting the base metals to size, we then TIG/MIG weld them into a billet. Next we heat them to 1200 degrees centigrade before setting the weld under the hydraulic press or power hammer.

We then draw out the billet, cut it into several sections, clean, re-stack, re-weld and repeat the process until the desired layer count and patterns are achieved.

The steel is forged to profile and drawn out to the desired thickness.

We grind all the fine profiles and bevels on our dedicated knife grinders before moving on to heat treatment.

No two knives are the same

Every blow with the hammer creates a truly unique pattern. Like a fingerprint, no two billets of steel are ever the same. Every Celery Patch Knife is distinctive and a true one-of-a-kind.

Every knife is born in fire

All Damascus knives start as individual sheets of steel. 1084 & 15n20. Similar to a croissant, we continue to forge together, draw out, re-stack and repeat the process. Low layer count is generally around 130 individual layers of steel, whereas a high layer count can be over 1000 individual layers.

It takes multiple days to create each knife

The forging process is slow and labour intensive. Each billet of steel has to anneal between forging sessions. The steel is ground back to a perfectly clean surface, cut, restacked, and then forged again. This process is generally done over the course of a week.